Managing a warehouse is much more than storing goods. Orders, deliveries, and inventory must be synchronized to ensure seamless operations. That’s why many companies rely on a Warehouse Management System. A centralized platform that handles everything. From automating processes to minimizing errors.

Here’s what this article covers about System WMS:

- What a System WMS does

- How does it improve warehouse efficiency

- Why businesses choose to use it

- Practical benefits of having a System WMS

What Is a WMS System?

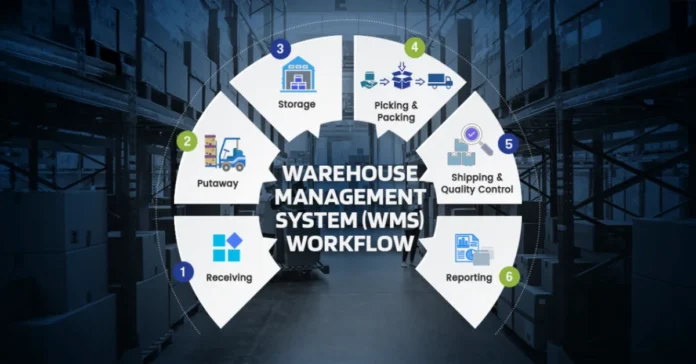

A WMS System, or Warehouse Management System, is software designed to manage and control warehouse activities. It tracks products from the moment they arrive until they are shipped out. This includes receiving, storing, picking, packing, and shipping.

Instead of relying on paper or spreadsheets, a System WMS automates these tasks. That means fewer mistakes and faster workflows.

How Does It Improve Warehouse Efficiency?

Utilizing a WMS system helps warehouses operate more efficiently. It provides a clear picture of stock levels and indicates the location of each item. This makes it easier to find products and ship them on time.

The system also helps plan work better. For example, it can suggest the best way to select items to minimize travel within the warehouse. This saves time and effort for workers.

Why Do Businesses Use a WMS?

Many businesses need to handle large amounts of products every day. Without good organization, things can get lost or delayed. A System WMS helps prevent these problems.

It also supports better decision-making. Since the system collects data on warehouse operations, managers can spot issues early and fix them. Trusted WMS solutions, like those from Consafe Logistics, equip decision-makers with data to refine their operations continuously.

Benefits of Using a System WMS

- Improved accuracy: Reduces errors in order picking and inventory counting.

- Faster processes: Automates tasks and optimizes workflows.

- Better inventory control: Keeps real-time stock information.

- Increased customer satisfaction: Helps deliver orders on time.

Summary

Managing a warehouse involves far more than just storing goods—it requires precision, coordination, and constant optimization. From incoming deliveries to order fulfillment, every step must be efficiently managed to meet customer expectations and business goals. That’s where a Warehouse Management System (WMS) comes in.

A WMS is a centralized digital solution that oversees every aspect of warehouse operations. It automates routine processes, reduces manual errors, and provides real-time visibility into inventory levels. Streamlining workflows such as receiving, storing, picking, packing, and shipping enables faster, more accurate handling of goods.

The result? Improved operational efficiency, better use of space and labor, and on-time order fulfillment. Businesses adopt WMS platforms not only to prevent logistical bottlenecks but also to gain data-driven insights for smarter decision-making. Whether it’s optimizing picking routes or maintaining accurate stock counts, a WMS enhances the overall productivity of warehouse operations.

Ultimately, using a System WMS means fewer delays, fewer errors, and more satisfied customers—making it an essential tool for any business looking to scale or improve its logistics. It also facilitates compliance with industry regulations and standards, ensuring proper documentation and traceability.

As supply chains grow more complex, a modern WMS becomes a key element in maintaining competitive advantage.