Modern businesses face mounting pressure to deliver products faster while controlling costs. Supply chain complexity grows as companies expand into new markets and serve increasingly demanding customers. Traditional logistics management approaches no longer meet these challenges.

Companies that rely on manual processes, spreadsheets, and disconnected systems struggle to maintain visibility across their operations. They lose time tracking shipments, face inventory discrepancies, and provide poor customer service. These inefficiencies translate directly into lost revenue and damaged relationships.

Third party logistics providers (3PLs) and businesses using their services need sophisticated technology to compete. The right logistics software transforms operations from reactive firefighting to proactive optimization.

The Hidden Costs of Outdated Logistics Management

Manual logistics processes cost more than most businesses realize. Staff spend hours entering data, reconciling discrepancies, and searching for information that should be instantly available. These tasks drain productivity and increase labor costs.

Poor visibility creates additional problems. You cannot optimize what you cannot see. Without real-time data on inventory levels, shipment status, and warehouse operations, businesses make decisions based on outdated information. This leads to stockouts, overstocking, and missed delivery commitments.

Customer expectations continue rising. Buyers expect accurate tracking information, flexible delivery options, and instant updates when problems occur. Companies using outdated systems cannot meet these demands consistently.

Communication gaps between different parts of the supply chain create delays and errors. When your warehouse management system cannot communicate with transportation software, or when inventory data exists in multiple disconnected spreadsheets, mistakes become inevitable.

How 3PL Software Transforms Business Operations

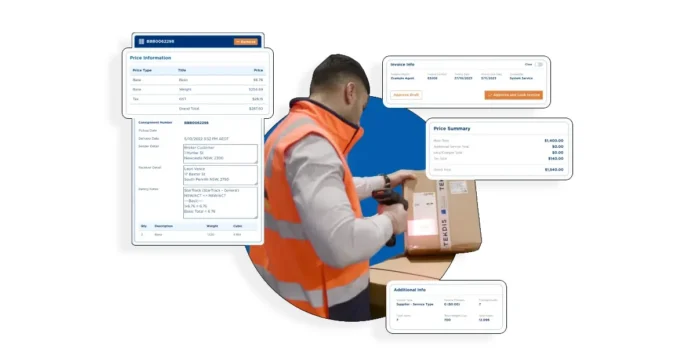

Third party logistics software creates a unified platform that connects every aspect of your logistics operations. Instead of juggling multiple systems and manual processes, you gain a single source of truth for all logistics data.

Real-time visibility transforms decision-making. Managers can see current inventory levels, track shipments in progress, and identify potential problems before they impact customers. This visibility extends to customers, who receive accurate updates about their orders without requiring manual intervention from your staff.

Automation eliminates repetitive tasks that consume staff time. The software automatically generates shipping labels, updates inventory records, sends customer notifications, and creates reports. Your team focuses on strategic activities rather than data entry.

Integration capabilities connect your logistics operations with accounting systems, customer relationship management platforms, and e-commerce sites. Data flows seamlessly between systems, eliminating manual transfers and reducing errors.

Warehouse operations become more efficient through optimized picking routes, automated inventory tracking, and digital documentation. Workers spend less time searching for products and more time fulfilling orders.

Essential Features Your Logistics Software Must Include

Comprehensive inventory management forms the foundation of effective logistics software. The system must track stock levels across multiple locations, handle lot tracking and expiration dates, and provide accurate availability information to all stakeholders.

Order management capabilities should support complex business rules, multiple fulfillment methods, and various customer requirements. The software must handle everything from simple single-item orders to complex multi-location shipments with special handling requirements.

Transportation management features optimize carrier selection, automate rate shopping, and provide shipment tracking. The system should support multiple carriers and shipping methods while maintaining visibility throughout the delivery process.

Warehouse management functionality guides staff through efficient picking processes, tracks inventory movements, and manages receiving operations. Mobile capabilities allow workers to access information and update records from anywhere in the facility.

Reporting and analytics capabilities provide insights into operational performance, cost trends, and customer satisfaction metrics. The software should offer both standard reports and customizable dashboards that display the information most relevant to your business.

Customer portal functionality allows clients to access order information, track shipments, and communicate directly with your team. This self-service capability reduces support requests while improving customer satisfaction.

Measuring ROI from Logistics Technology Investment

Logistics software delivers measurable returns through multiple channels. Labor cost reductions often provide the most immediate and visible benefits. Automation eliminates manual tasks, reduces errors that require correction, and allows staff to handle higher volumes without proportional increases in headcount.

Inventory optimization generates substantial savings by reducing carrying costs and minimizing stockouts. Better visibility into demand patterns and lead times enables more accurate purchasing decisions and lower safety stock requirements.

Customer satisfaction improvements translate into business growth through higher retention rates and increased order volumes. When you consistently meet delivery commitments and provide excellent service, customers become advocates for your business.

Operational efficiency gains compound over time. Faster order processing, reduced errors, and improved communication create a positive cycle that continuously improves performance.

Compliance and audit costs decrease when the software maintains detailed records and generates required documentation automatically. This becomes particularly valuable for businesses in regulated industries or those serving enterprise customers with strict requirements.

Choosing the Right 3PL Software Partner

Software selection requires careful evaluation of your specific needs and growth plans. The right solution must handle your current volume while scaling to support future expansion. Consider both your immediate requirements and your three-to-five-year growth projections.

Implementation support makes the difference between success and failure. Look for vendors that provide comprehensive training, data migration assistance, and ongoing support. The transition period is critical, and you need partners who will ensure smooth operations throughout the process.

Integration capabilities determine how well the new software will work with your existing systems. Evaluate the available APIs, pre-built connectors, and custom integration options. Seamless data flow between systems is essential for maximizing efficiency gains.

Total cost of ownership includes more than just software licensing fees. Factor in implementation costs, training requirements, ongoing support fees, and potential customization expenses. A lower-priced solution that requires extensive customization may cost more than a higher-priced option that works well out of the box.

Vendor stability and roadmap alignment affect your long-term success. Choose partners who demonstrate consistent growth, regular product updates, and strategic direction that matches your business needs.

The logistics industry will continue evolving rapidly. Businesses that invest in modern technology today position themselves to capitalize on future opportunities while competitors struggle with outdated systems. Your logistics software decision impacts not just current operations but your ability to compete in tomorrow’s marketplace.